“The DNA of the TECOFI group lies in the challenge, dynamism, resilience and above all in its men and women who make up the company and who shape its history.”

Fabien FAYARD – Sales Director

Our ambition: to offer quality solutions adapted to the needs of our partners throughout the world. The guarantee of an independent French manufacturer with technical expertise and a reputation in over 80 countries.

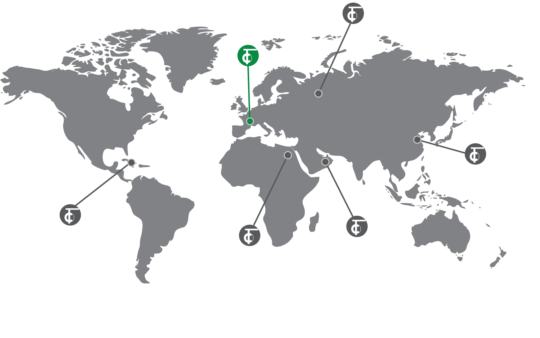

100%-Tecofi subsidiaries

A global presence ensured and relayed by our subsidiaries in the four corners of the world.

Countries

Our strength: adapting to provide the right solution worldwide.

of our business is international

Our international presence is historic and continues to grow.

Based in Corbas, in the Lyon region, our head office is comprised of:

We have a large stock of valves up to DN1200 which allows us to be reactive and to offer you flexibility and fast delivery.

We have 7 assembly lines for assemblies and adaptations to meet the most specific requirements. Specialists carry out all assemblies. A test area allows us to carry out quality controls on our premises (material and dimensional controls, hydraulic leak tests, manoeuvre tests, etc.).

Two new hydraulic test benches allow us to test our valves semi-automatically up to DN1600 (PN16) / DN1000 (PN25) / DN600 (PN40). These test benches are approved by APAVE.

address :

83 rue Marcel Mérieux

69960 Corbas – France

Based in Genas also in the Lyon region, our offices are located in a building built to the highest environmental standards (HQE Aménagement certified). They include large work areas, reception and relaxation areas to receive all our partners and improve the quality of life at work for our employees.

Adress :

8 rue Joseph Nicéphore Niépce

69740 Genas – France

With 5 subsidiaries and a large network of partners, we are present in more than 80 countries worldwide.

Our dedicated sales teams work on a daily basis to ensure that we are always close to our partners. All of our employees are attentive to the needs and developments of the market, and are able to respond quickly and effectively to your projects.

Our documentation and catalogues are available in many languages: French, English, Spanish, Russian, Chinese…

—

Diversity

Diversity is at the heart of our business. Our international presence and open-mindedness make us a cosmopolitan company working with many partners from different cultures.

Dynamism

Our ambition, agility and boldness allow us to develop our growth with energy. Always on the move, we are open to opportunities so that every day is a new adventure.

Human

Teamwork is one of the pillars of our corporate culture thanks to the

conviviality that has always prevailed within Tecofi. We develop our confidence in each employee so that each one can flourish in his or her missions.

The French Fab is made up of French companies and industrial sites that aim to develop French industry.

As a French company, TECOFI is committed to the FRENCH FAB movement to:

Contribute to the international influence of French industry

Accelerate the transformation of industry in France

Embody the prosperous future of French industry and the attractiveness of its professions.

“As a major player in the supply of water valve equipment, we must, like our customers, be exemplary when it comes to protecting the environment.”

TECOFI is committed to the environment in order to preserve natural resources and improve water resource management (treatment, distribution, etc.). Within the framework of the ISO 14001 certification, our strategic vision is oriented towards quality and respect for the environment in order to ensure the development and sustainability of our company in an ethical and responsible manner. An environmental management system has been put in place to manage the impact of our activities on the environment.

Quality and Environmental Management Manual

Quality and Environment Policy

Environmental charter

Social responsibility charter